What To Do When Your Bottle Jack Is Too Short?

Our Isuzu NPS has 19.5” super single tyres. From factory, the tyres are 17”. So when you’re changing a tyre with the factory-supplied bottle jack, it doesn’t have enough travel to lift the wheel off the ground.

Clearly, this is a problem.

Now you could of course buy a bigger one. But the supplied jack is nice and compact, fits neatly in its spot and has plenty of capacity for our needs. So we wanted to keep this one.

A Short Jack

The standard supplied bottle jack is rated to 5 tonnes. Its stroke is about 125mm. A wind-out ACME-threaded screw on top effectively gives you a “chock” of about 70mm. But with super singles fitted, it’s not enough.

What to do?

There’s a couple of simple solutions. The first is to carry a 3 or 4 inch thick block of hardwood. You can sit the jack on this and it will give you enough height under the axles.

We did something slightly different. I wanted something a bit lighter than a big heavy chunk of hardwood.

Using What We Had

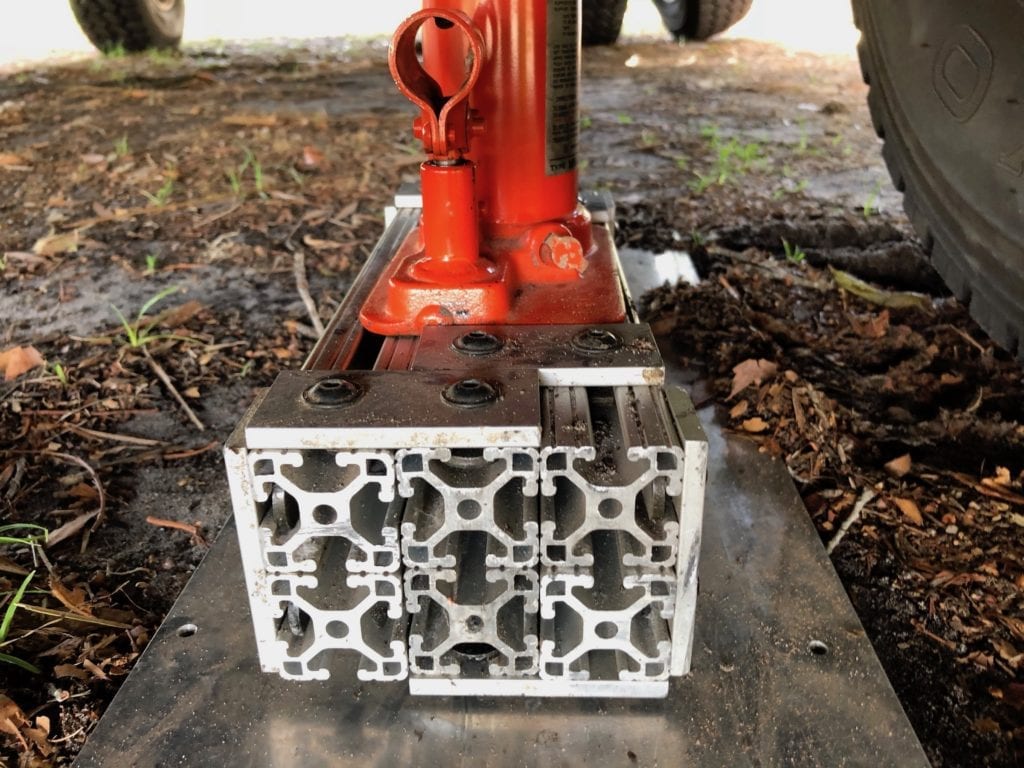

We had a stack of 80/20 offcuts. 80/20 is a modular system used to build machine guards, frames of all descriptions and even entire machines. The aluminium extrusions are lightweight yet really strong.

So I bolted six pieces together to form a solid block, about 310mm long. There’s three rows, two high. Each piece is 38mm x 38mm (1-1/2″), so we get another 76mm of height.

I used the standard 80/20 flat brackets, T-slot nuts and bolts to bolt it all together.

By positioning the flat brackets in the right spot, they hold the jack in place so it can’t slide around. And even if some of the bolts snapped while the jack was in use, the whole thing wouldn’t fall apart.

The result is a lightweight chock that’s easy to use and easy to pack away. This gives us an extra 80+mm of height under the jack, which is plenty to safely change a tyre.

Don’t Forget The Base Plate

I also had a piece of 8mm aluminium plate. It’s about 700mm x 250mm and is perfect under the bottle jack as a base plate in soft soil or sand.

It spreads the load over a much greater area and prevents the jack base from disappearing into soft ground.

If you’re doing a lot of off-road driving, you really do need to take something like this with you. Without a base plate, the jack will simply push into the soft ground. So you won’t be able to jack the axle high enough to change the tyre.

Even worse though, jacking a heavy vehicle on soft ground is dangerous. The last thing you want is for the truck to slip off the jack.

Again, this base plate is light, easy to store and won’t rot over time like timber does.

In Summary

If you’re thinking of getting super singles on your light truck, remember to check the jack. Make sure it stills lifts the truck high enough. You don’t want to be caught out in the middle of nowhere…

And make sure you can do it safely.

Any questions or comments? Go to the Comments below or join us on Pinterest, Facebook or YouTube.

Any errors or omissions are mine alone.

Get your Traveller’s Guides

… and a whole lot more at our FREE RESOURCES Page!

Note: We are not affiliated with 80/20 Australia in any way.

Go here for more How-To Guides and tips.

It’s better to buy bigger one.

I bought a 8ton jack to use on my 4ton F250. Agree, buy a bigger one. If you can afford the truck, you can certainly afford a bottle jack.

Very true Andre. Cheers, Andrew

The compression loads should be along the length of the extrusion channels. I would orient it 90 degrees vertically to the way you have it in the photo.

But then it would be too tall. I made the block 3 channels wide x 2 high to spread the load across a bigger footprint. This helps prevent the block from sinking into soft ground and is more stable.

Cheers, Andrew