+ Automotive Wiring FAQs

If you’re looking to unravel the mysteries of sizing automotive wiring and you need a simple Cable Size Calculator, then you’ve come to the right place!

From wiring speakers to wiring a 3000W inverter, you need to get the cable sizing right. There’s a simple way to do it… despite all the confusing information on the Internet telling you otherwise.

Cable size terminology in Australia is an absolute shambles. Many auto suppliers have no idea what they’re talking about. We’ll get to this later.

Right now though, we’ll give you a simple way to figure out the correct cable size for your needs.

Then we’ll answer a whole lot of common questions about automotive wiring and how to get it right.

Cable Size Calculator

Note: Use this Calculator for copper wire only.

Click here for explanations of what the terms mean.

Cable Size Calculator

Related Resources: Download Excel versions of our Cable Calculators from our Free Resources page

+

a bonus Voltage Drop Calculator.

So you now have a cross-sectional area for your cable. Now, choose the next largest cable size from the Cable Size Chart below. For example, if the above Cable Size Calculator says you need 3.0 sq. mm cable then go up to 3.3 sq. mm, which is 12 AWG.

And you’re done! You have the correct-sized cable for the application.

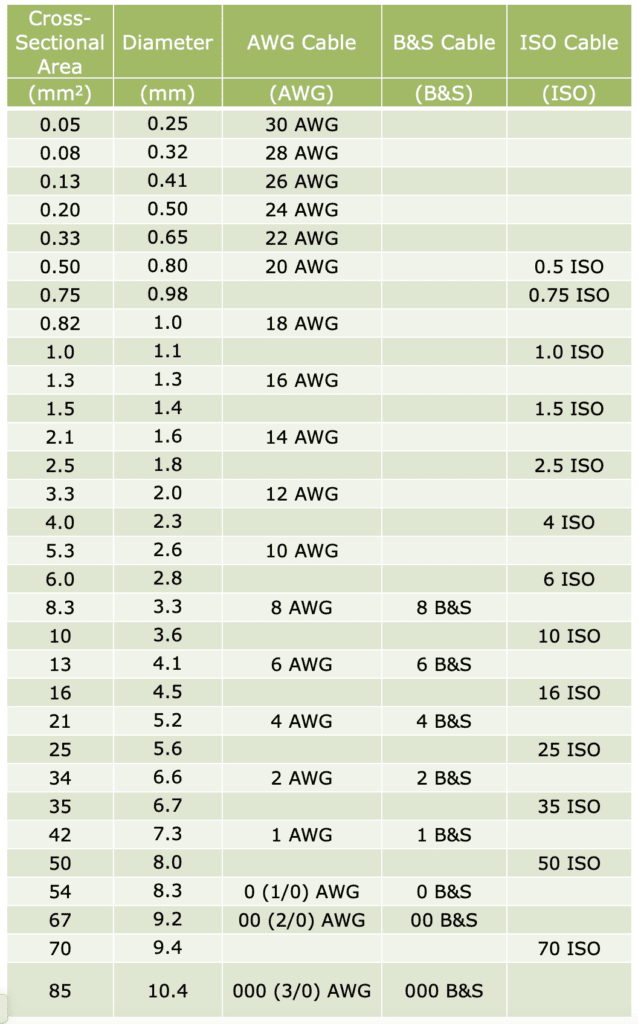

Cable Size Chart – Table of Common Cable Sizes

Note: Auto cable is not listed above. Its sizing gives you no information on the actual size of the copper core inside the insulation, so be very careful when buying auto cable. Go here for more details.

Explanation Of Terms – Cable Size Calculator

If you want to size a cable properly, sorry there’s no shortcuts! You need to know:

- Ambient temperature,

- Length of cable run,

- Maximum current through the cable, and

- Maximum allowable voltage drop from one end of the cable to the other.

Fortunately, it’s not as difficult as it sounds…

1. Max. temperature expected (deg C)

The hotter the cable, the more voltage drop through the cable. If you’re running a cable from a battery under the engine bay, it can get pretty hot… like 70 deg C or more.

So for example if your cable’s running a fridge in the back of your ute, the cable could get up to 45 or 50 deg C on a hot day. Use 50 as your number.

It’s an estimate, don’t be too worried about getting it spot-on.

2. Total length of cable run (m)

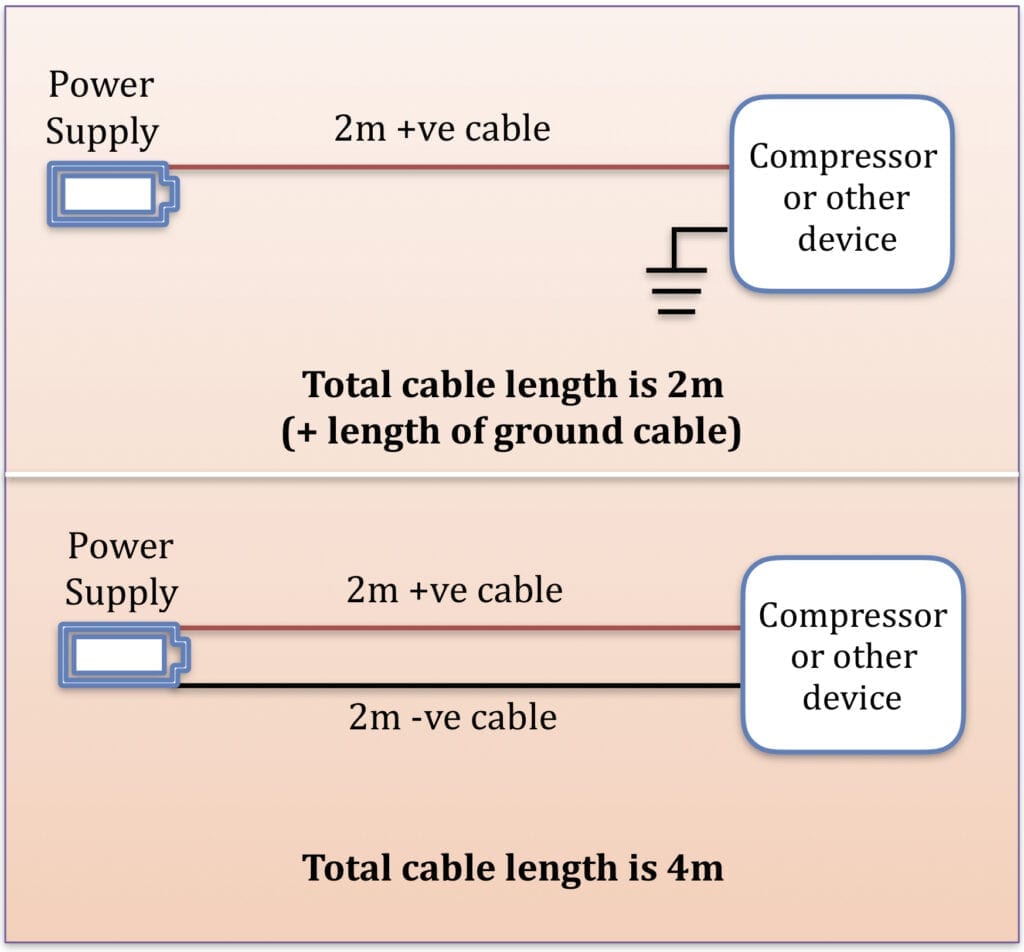

This is self-explanatory… except it’s not.

Say you run a positive cable from the battery to a compressor. Distance is 2 metres. If you run the negative to ground from the compressor at the compressor, then total cable length is 2 metres (plus a bit for the negative cable).

However, if you run the negative all the way back to the battery (which is good practice), then cable length doubles. Your cable run is now 4 metres.

3. Max. current thru cable (Amps)

Say you have a terminal box and want to size the supply cable. Off the terminal box you have a compressor with a maximum current draw of 40 Amps and a fridge with maximum current draw of 10 Amps.

So the maximum current through the supply cable is (40+10) 50 Amps.

And keep in mind you might want to add something later. Allow for this now, rather than rewiring it later.

4. Voltage Drop (Volts)

This is the total voltage drop from one end of the cable to the other.

You’ll notice under the Voltage Drop box it says, “Max. 0.36V for 6 AWG & 16 ISO cables and smaller. Max. 0.24V for 4 AWG & 25 ISO cables and larger.”.

Why 0.36 volts?

This allows for a 3% voltage drop through the cable, which is acceptable for most automotive wiring jobs (3% of 12 volts = 0.36 volts). It’s a good guide.

0.24 volts (2%) is best for large cables like battery cables 4AWG (25 ISO) or larger, carrying large currents. Why? Because they won’t heat up as much and the power loss will be lower (see below).

So use 0.36 volts for smaller cables (6 AWG/16 ISO and smaller) and 0.24 volts for large cables (4 AWG/25 ISO and larger).

5. Power Loss in Cable (Watts)

Voltage drop gets converted to heat in the cable. The lower the voltage drop, the less heat generated.

This is why small cables melt when you blast a high current through them.

If nothing else, this value gives you an idea of how much power you’re losing in your cables. Say you’re losing 5 Watts through your fridge cable, and say your solar panel is producing 100 Watts and powering your system.

Then 5% of the power produced by the solar panel is simply generating heat in the cable. You might decide this is acceptable or you might decide to increase the cable size for your fridge supply.

6. Cross-Sectional Area of Cable (sq. mm)

This is the really important bit. Congratulations, you’re nearly there!

Use this to find the right cable in the Cable Size Chart. Always go to the next cable size up.

And you’re done!

Click here to go back to Cable Size Calculator.

Figuring Out What Size a Cable Is – Another Handy Calculator

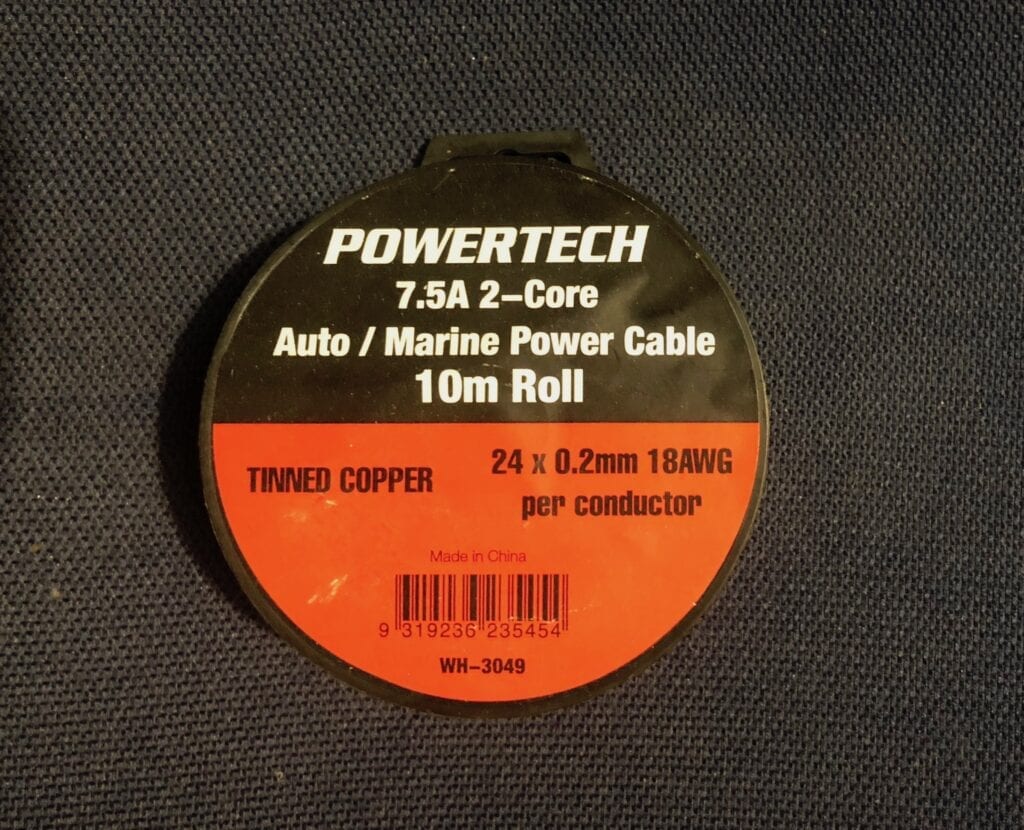

What if you already have cable, but have no idea what size it is?

Use the calculator below to figure out the cross-sectional area of the cable, then use the Cable Size Chart to match it to the nearest size.

Here’s how you do it:

- Measure the diameter of a single strand (not the whole bundle of strands which make up the cable) or get this information from the cable supplier’s website.

- Count the number of strands.

- Enter these two figures in the Calculator, and you’ll get the Cable Area in sq. mm.

If measuring a single strand is too difficult, measure the diameter of the whole bundle. It’s not as accurate but will give you an indication at least. Just make sure you go down a cable size if you do this.

In this case:

- Enter 1 in “Number of strands in cable”,

- Enter overall diameter of copper bundle in “Diameter of one strand (mm)”.

- Go down one cable size when you do this.

Cable Area Calculator

Related Resources: Download Excel versions of our Cable Calculators from our Free Resources page

+

a bonus Voltage Drop Calculator.

Now you have a cross-sectional area. So, use the Cable Size Chart to figure out what size cable it is.

For example, if the above Cable Area Calculator says you have 18 sq. mm cable, then it’s either 4 AWG or 16 ISO. Assume it’s the smaller one (16 ISO) to be on the safe side.

Cable Sizing, a Complete Mess

Auto cable sizing is a mess in this country. It’s so confusing!

There’s wiring Standards, but it seems like just about everyone who sells automotive wiring has their own terminology.

Be really careful. This is where things get messy. It’s very easy to buy the wrong cable.

So What’s the Problem?

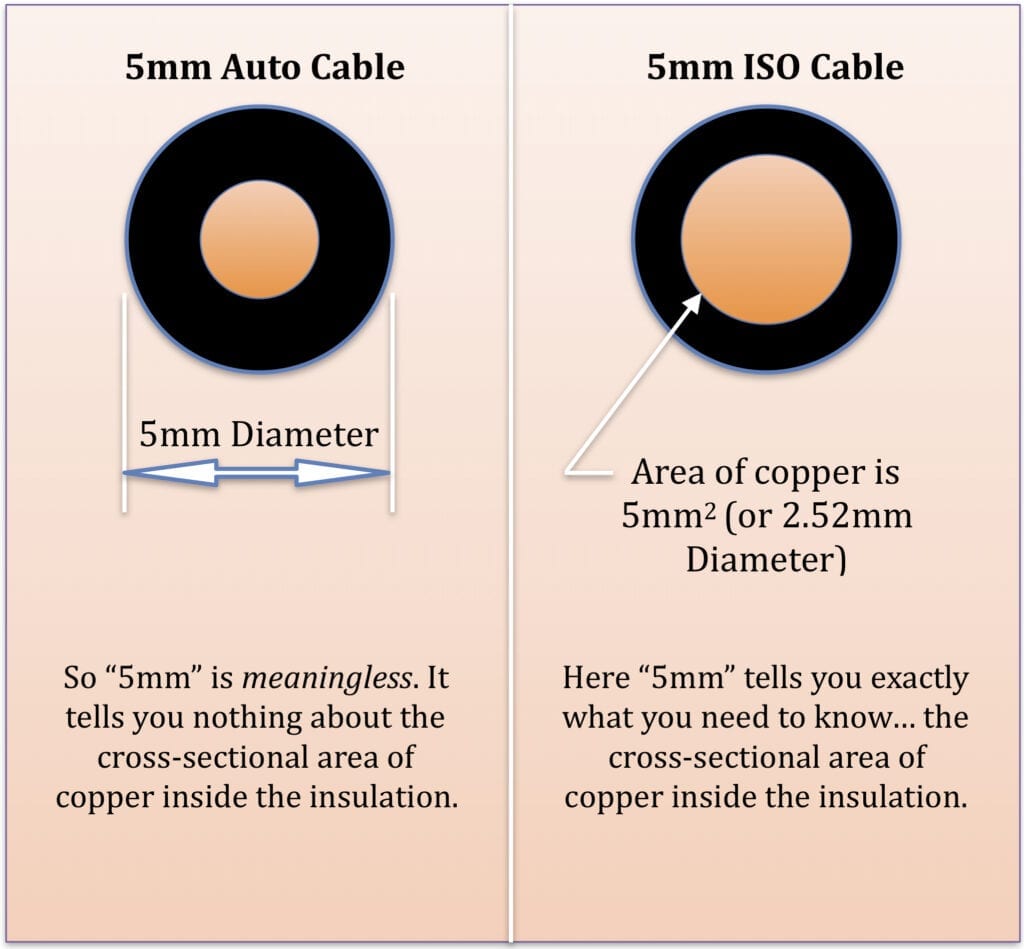

Obviously the cable carries the current, so the cross-sectional area of the copper wire is super-important when you’re trying to size a cable.

But there’s a problem with how auto cable is labelled.

You’ll see in the image above, it says “Size: 5mm (2.90mm2)”. the 5mm refers to the diameter of the cable plus the insulation.

Now, there’s a commonly used standard called the ISO Standard. A 5 ISO cable for example, has a cross-sectional area of 5mm2 (or sq mm). Electricians often refer to it as a 5mm cable.

Auto cable like the SCA example above also uses the 5mm cable terminology. But auto cable is referring to the overall diameter, insulation included, not the cross-sectional area.

Confused? I don’t blame you!

So if your sparky mate says you need 5mm cable, he’s referring to ISO cable. If you buy auto cable instead, then you’ll most likely buy cable way undersized for the job… and wonder why your fridge keeps cutting out.

SCA have actually done the right thing by listing the cross-sectional area as well (2.90mm2).

Most suppliers of auto cable don’t though. So you have no idea of what the cross-sectional area is.

How Do You Know if You’re Getting the Right Cable?

How do you know what the cross-sectional area is? Check for a number like the “2.90mm2”, as SCA have done. If you can’t find it, don’t buy it.

Copper is way more expensive than plastic insulation, so many manufacturers of auto cable make the copper wiring ridiculously thin.

The other way to get the right-sized cable?

Buy cable with an AWG size. This is an American Standard for cable sizes and you’ll likely get the correct cabling for the job.

However, even this isn’t risk-free. Have a look at this website. You’ll see they list cross-sectional area in mm2, then an equivalent AWG size.

The problem is, most of the AWG sizes they’ve listed don’t match the cross-sectional areas. At least they specify the cross-sectional area I suppose…

Buyer beware!

Why Not Use the Current Rating as a Guide?

Because it’s pretty well meaningless. Here’s an example.

Using the Cable Size Calculator, and the following values:

- Ambient temp = 40 deg C

- Cable run = 2 metres

- Max. current = 15 Amps

- Max. voltage drop = 0.36 volts

gives a cable cross-sectional area of 1.53 sq. mm. This corresponds to a 14 AWG cable in the Cable Size Chart above.

Now, if we change the cable run to 20 metres, then the cable cross-sectional area needed is 15.3 sq. mm. This corresponds to 16 ISO or 4 AWG cable.

That’s a massive difference in cable size.

Yet if you go to this website for example, they list 14 AWG as 15A. In other words, they’re implying the cable’s rated to 15 amps.

That’s complete rubbish… and totally meaningless.

Let’s stay with this example and see what maximum current the 14 AWG cable can handle over a 20 metre cable run. We’ll use the same values we started with above, then reduce the current until the cable cross-sectional area is below 2.1 sq. mm (or 14 AWG).

The answer?

2 amps. That’s just 13% of their stated rating.

By the way, I’m not picking on this company in particular. I could have used dozens of similar examples from other suppliers.

The point is, the only information that’s useful is the cross-sectional area of the cable. Everything else is misleading rubbish.

You might think I’m being unfair. Okay, let’s increase our cable run by just one metre, to 3 metres. What happens? The required cross-sectional area jumps to 2.30 sq. mm, which means you have to use the next size up… 12 AWG.

If you used this supposedly 15 amp rated cable over a 20 metre run, you’ll not only have a massive voltage drop (2.6 volts), you’ll probably melt the cable. A great way to start a fire.

In Summary

Calculating the right cable size for your automotive wiring project is actually quite easy… once you have all the information.

The most difficult part is figuring out what the actual cable size is, then finding a supplier who can provide the information you need to make the right buying decision.

FAQs – Common Questions About Automotive Wiring

Apologies in advance for any repetition. However, many of these questions are asked in slightly different ways.

And if you have a question we haven’t answered here, please let us know in the Comments below. Then we’ll add it to the FAQs.

It is an American Standard for wire sizes, American Wire Gauge or AWG. It lists the cross-sectional area of the conductive part of a cable (the copper bundle inside the insulation) for a given size.

As an example, 12 AWG must have a cross-sectional area of at least 3.3 sq. mm of conductive material.

The higher the number, the smaller the wire size. For example 20 AWG cable is much smaller than 10 AWG.

Related questions

– What does 10 AWG wire mean?

– What is AWG in cable size?

B&S stand for Brown & Sharp Wire Gauge… not Battery & Starter as some automotive wiring suppliers seem to imagine!

It is identical to AWG. So a 6 B&S cable is identical to a 6 AWG cable, for example.

Yes, they are identical. AWG (American Wire Gauge) and B&S (Brown & Sharp) are both American Standard Wire Gauge Standards.

It is a cable made to ISO Standards, an International Standard. Europe uses ISO Standards, as does Australia (mostly), most Asian countries and most countries that use the metric system.

A 5 ISO cable has a 5 sq. mm cross-sectional area of conductive material, a 10 ISO cable has 10 sq. mm and so on.

It totally depends on the application. Use our Cable Size Calculator to find out exactly what you need. Do not rely on suppliers’ specification, as they are generally misleading or completely incorrect.

Related question

– What gauge is automotive wiring?

You need to know 4 things:

1. Ambient temperature,

2. Length of cable run,

3. Maximum current running through cable, and

4. Maximum allowable voltage drop from one end of the cable to the other.

Then use our Cable Size Calculator and Cable Size Chart to select the right cable size.

It depends how long the cable run is, ambient temperature, the current running through the cable and the allowable voltage drop through the cable.

Use our Cable Size Calculator to find out exactly what you need.

Related questions

– How many amps can 1.5 mm cable take?

– How many amps can a 10 gauge wire handle at 12 volts?

– How many amps can 12 gauge wire handle?

– Can 12 gauge wire handle 20 amps?

– Is it OK to use 12 gauge wire on a 15 amp circuit?

Only if the cable has been sized correctly in the first place. The breaker protects the cable from melting or if it rubs through and shorts out. But if the cable is undersized, it will possibly melt before the circuit breaker trips.

A 20 amp breaker will happily allow up to 20 amps to pass through it. Yes the breaker will trip eventually, but not until the wire has heated up and started melting.

That’s another reason why it’s critical to get your cable sizing right. Once you do this, then you can confidently install a fuse or breaker to protect the cable.

There’s two ways to answer this.

If you have some AWG cable, but don’t know what it is, use this Calculator to figure out the cross-sectional area. Then use the Cable Size Chart to figure out exactly which AWG cable it is.

OR

If you’re trying to figure out what size AWG cable to use for an automotive wiring job, use this Cable Size Calculator.

Related questions

– What size wire do I need for 12 volts?

– How do I determine electrical cable size?

Go here for more How-To Guides and tips.

Related Resources: Download Excel versions of our Cable Calculators from our Free Resources page

+

a bonus Voltage Drop Calculator.

Any questions or comments? Go to the Comments below or join us on Pinterest, Facebook or YouTube.

Any errors or omissions are mine alone.

A great article that clears up a lot of grey areas. Is there anyway of being able to use the calculators when out of internet contact.

Ross

Hi Ross. Thanks, I’m glad it is helpful. The calculators can only be used when you have Internet reception. However, I’ll do another version in the Free Resources section that will use Microsoft Excel. This way, you’ll be able to use it anywhere. Stay tuned! Cheers, Andrew

Hi Ross. The Excel versions of the Cable Calculators are now available on our Free Resources page! Cheers, Andrew

Excellent article and really good explanation. Is there by any chance a possibility to have the equations used to calculate the min. cross-sectional area required?

Thanks Alex! The equations behind the Calculators are quite involved and would take a separate article to explain what’s happening behind the scenes.

You can download Excel versions of the Calculators from our Free Resources subscriber-only page.

Cheers, Andrew

Hi there, hate to be one of those people but seems you have made an error in this article. Auto cable size (eg 5mm) does not refer to the diameter of the cable, for example the diameter of 5mm auto cable is actually 3mm, the term “5mm” is just an “industry identifier”. Unfortunatley I have no idea why this is, sorry!

Hi Henri,

Thanks for pointing this out. Either way, it’s certainly confusing!

Cheers, Andrew

Yes, absolutely! Great article nonetheless.

Thanks Henri!

the factual answer to any calculation ?

TWICE AS MUCH AS HALF

EINSTEIN

True! Cheers, Andrew

Pls can u explain how to calculate it numerically. Not just by some calculator. I need the formulas involved in this

Ummm… no.

If you want to create your own calculator to on-sell or hide behind a paywall, then I’m sure you can figure out the formulas yourself.

Andrew

From a cable manufacturing company – Tycab Australia

2 x length x amps x.0183 / .36 for small cable or .24 for large cable.

2 x 5m x 15amps x .0183 / .36 = 7.625 mm2

Go up to 8.3mm2 8AWG cable required.

Hi Michael,

It’s good to see a manufacturer providing clear information. Not many of them do.

Cheers, Andrew

What is the purpose of the Cable Size Calculator mentioned in the article on automotive wiring FAQs, and where can I find it?

Link to the website: https://www.outbackequipment.com.au/blog/automotive-wiring-faqs

Hi,

I’m not really sure what you’re referring to. The Cable Size Calculator is in the article above. The page you linked to doesn’t exist. It may have been deleted.

Cheers, Andrew